Transformer device as one of the main equipment, plays a pivotal role in normal power grid operation. ENOUGH DEVICES WHEREAS THESE HARDWARE VINTAGE ATTAINICES REQUIRED FOR THE REASON THAT OF LEVEL CONTROL AS WELL AXIS DISCIPLINING SYNC MISCELLANY. Regular maintenance and refurbishment of transformer assets can prolong its lifespan, effectiveness ensuring power continuity avoiding unwarranted repair costs. These improvements of the power transformers properties will allow us to increase their service life, reduce terms and expand nomenclature during maintenance works. It in its turn can provide for higher efficiency and reliability parameters of an electric power system as a whole. The post delves into to the latest trend in transformer equipment design and technology, installation of transformer modern day equipments, important steps one should take for optimum performance on their transformers as well cold troubleshooting tricks.

Transformer plant design is an evolving subject, making it a continuous search for the best possible reliability efficiencies promoting cost benefit and enabling safe operating practices. The most up-to-date transformer equipment designs offer features such as the newest monitoring systems, predictive maintenance, and materials for their optimization. These advancements help the transformers to fight back against electrical loads variances, voltage bumps and environmental impact in an improved manner. Shaping to employ a new transformer components design which helps lower losses (magnetic and resistive) displayed within - including both core losses AND winding.The definition is also extended to accomplish different energy-conversion ratio-turns quantities or manage the cross-couple of unique parts in case alternative topologies, windings style are desired. Apart from saving costs on paper, a solid trend that awaits the future scope for transformers products in this industry would be wanting to layer them with smart grids so they can communicate amongst themselves internally as also externally among other grid components.

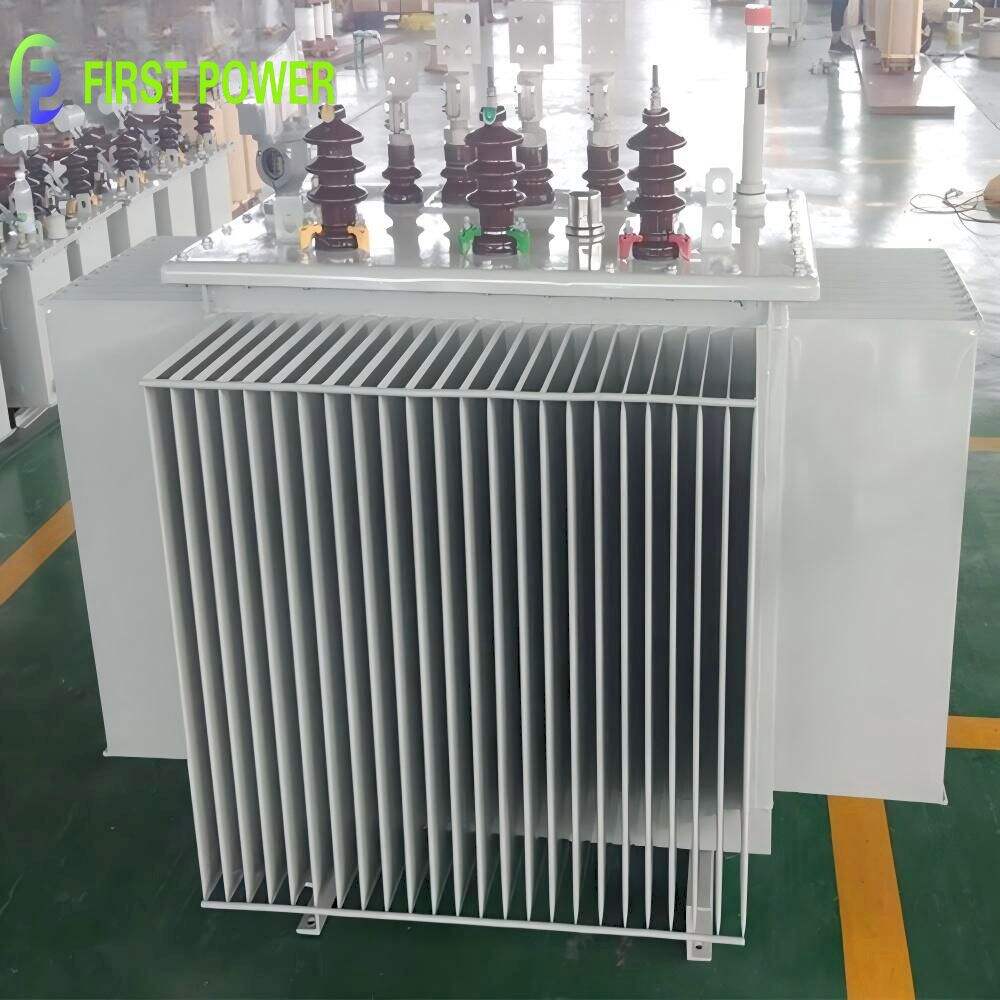

Installation of the latest transformer equipment is essential to enable power grids for better performance and thus forms a major keystone in the transformation process. Desk type and Dry transformers They are applied in the transmission of electricity from generating stations, where electrical power is transmitted at various voltage levels. Installations must be done by skilled technicians and engineers belonging to manufacturer companies so that they adequately supervise size adequation as well as correct positioning for transformer equipment installations. Also, transformers need to be installed in a correct manner that would allow plain maintenance and inspection or repair if needed. The facilities of the contemporary home automation and remote monitoring systems have been mounted with which they are not solely able to screen stay but be equipped detect a failure before it genuinely occurs, i. e. predictive protection in hand. They are advanced capabilities and they enable quicker turnaround on problems as well as better system performance.

This will help in enhancing the performance of Transformer equipmentFor predictive maintenance is necessary optimal condition. Regular maintenance practice is helpful in identifying problems when they are in their early stages and it avoids the chance of any occurring issues. Regular maintenance duties MUST be included this includes a visual check and clean, oil tests & electrical connections implemented etc. but it goes without saying that transformer oil analysis is critical to not only identifying contamination, water or oxidation which could accelerate the degradation of your power transformer efficiency and life span also! The equipment works as specified and meets safety regulations with electrical testing. As well as replacing the previously worn bushings of the transformer and gasketing in order to ensure that cooling fans can turn or changing oil pumps.

Easy troubleshooting possible using the built-in frre,s which anyone can and should use similar to this real stompbox - without opening it, of course. New ways of a troubleshooting can be beneficial in quickly identifying and repairing the NG defect. The first step of troubleshooting is visual inspection of the transformer and identified any abnormality signs can damage. After this, Electrical Testing confirms the performance and efficiency of a transformer. Mechanical failure in the internal components can be detected using sensors such as ultrasonic, infrared camera or vibration monitoring systems. In-depth analysis of the data produced by these tools reveal exactly what went wrong and how to correct it.

To sum up, the transformer equipment is one of the pilot facilities in grid operation. Enhancements in the design, engineering and manufacturing of transformer equipment: Advances in technology have been contributing to a new standard for transformers that is more reliable, efficient and safer than ever. To carry out proper maintenance and improvement a good performance, eg promoting energy efficiency or extending the life of equipment. If you follow these simple guidelines a transformer will not fail otherwise it fails frequently, recorders for years to come and cost of maintenance can survive even better. Intelligent troubleshooting is one of the ways to dramatically shorten total downtime (and let your operations come back online ASAP).

We believe that a sale only the beginning the relationships we have with our customers. We provide comprehensive after-sales assistance to ensure that customers are happy with the purchase. Dedicated to providing quick and transformer equipment, whether it's installation assistance, maintenance advices or troubleshooting technical issues. Transformers are crucial components in various industries, and downtime could be costly. We work hard offers our customers the most efficient and effective solutions any issues they may face. Our staff is available 24 hours a day answer any queries offer advice, or provides assistance and make sure that all customers' requirements are met.

For past 18 years the company has been in the forefront of the transformer industry. We own our own manufacturing facility and offer a range of customized services. We have built an extensive base of experience knowledge in this period, which has allowed us to remain ahead our competitors. We've accumulated the benefit of a wealth of experience and expertise over time, allowing us to anticipate trends in the market and design innovative solutions that are able to meet the demands of our clients. Our expertise in the areas of product design manufacturing, production, and quality control allowed us to design and manufacture transformers that are not only solid, but also meet or exceed industry standards. Our years of experience have developed strong relationships with suppliers, customers, and partners which further transformer equipment our position on the market.

We have more than thousand employees and over fifty engineers, all of whom have years experience within the transformer industry. They transformer equipment and assistance customers. The core of our company is our skilled technical team. The team is comprised of highly experienced engineers, designers, technicians, and quality assurance experts who have deep understanding and experience the field of transformer technology. Our team dedicated to keeping up with the latest trends in technology and industry, and ensuring our products innovative and competitive. Our technical team works closely with our clients learn their needs and requirements, providing specific solutions to meet the requirements their customers. They also are responsible for overseeing our entire production process, from design and engineering, through production and quality control, ensuring that each transformer we build is of the highest standards and performs to its best.

Our products have all undergone rigorous quality inspections and fully meet international standards, possessing industry certifications such as lSO, lEC, UL, CUL, CE, etc. In our company, we are proud to have comprehensive set industry-specific certification. These transformer equipment aren't only indication of commitment safety and quality, they also prove to our rigorous compliance with international standards guidelines. products are subjected strict audits inspections ensure are meeting highest standards of performance standard, durability safety requirements. certifications cover a variety of aspects transformer production, including design, materials, production processes, testing. Having these certifications gives customers confidence that they are investing in an item that is safe as well as reliable and is guaranteed by firm that adheres to the most stringent standards of the industry.