Improving Our Understanding of Electricity using Transformers

Transformers In The World Of Electricity. Designed to distribute electrical energy, so that the electricity can be used effectively and safely these machines ensure productivity at home. In its simplest form, a transformer is simply a device that regulates the voltage of electricity as it passes through, increasing or decreasing its strength to control it for purposes where less powerful supply or greater input speed required.

In some contexts, like factories and manufacturing facilities where machines used to perform production processes are fixed installations requiring a very stable source of power for equipment performance; industrial power transformers become crucial. They are the unspoken guardians performing invisibly from backstage to make sure that energy, required for running these machines effectively is dispatched accurately.

All that electricity is generated at a power station and then travels along wires to get where it needs to go. During its journey, it encounters a transformer and the job of this transformer is to step up the voltage in electricity. Transformers increase the power of an electrical current so it can travel long distances without losing its strength. After the voltage has been changed, what follows is that same electricity reaching its destination; machines need to operate on this standardized supply.

Yet power transformers in factories have far from the widest reach of industrial output. These devices are major for transferring electricity in a safe and efficient manner to different places like homes, schools etc. Life without transformers would mean that we could not be able to operate a plethora of everyday electrical items such as computers, phones or even something as modest as flicking on the light switch.

Industrial power transformers are efficient in that they lose considerably minimum amount of energy when transmitting. However, on a long way of electricity passes through wires it may lose its power. The answer is transformers of course, with these whipping the voltage back up so far less energy disappears as a current chases after it to make everything work.

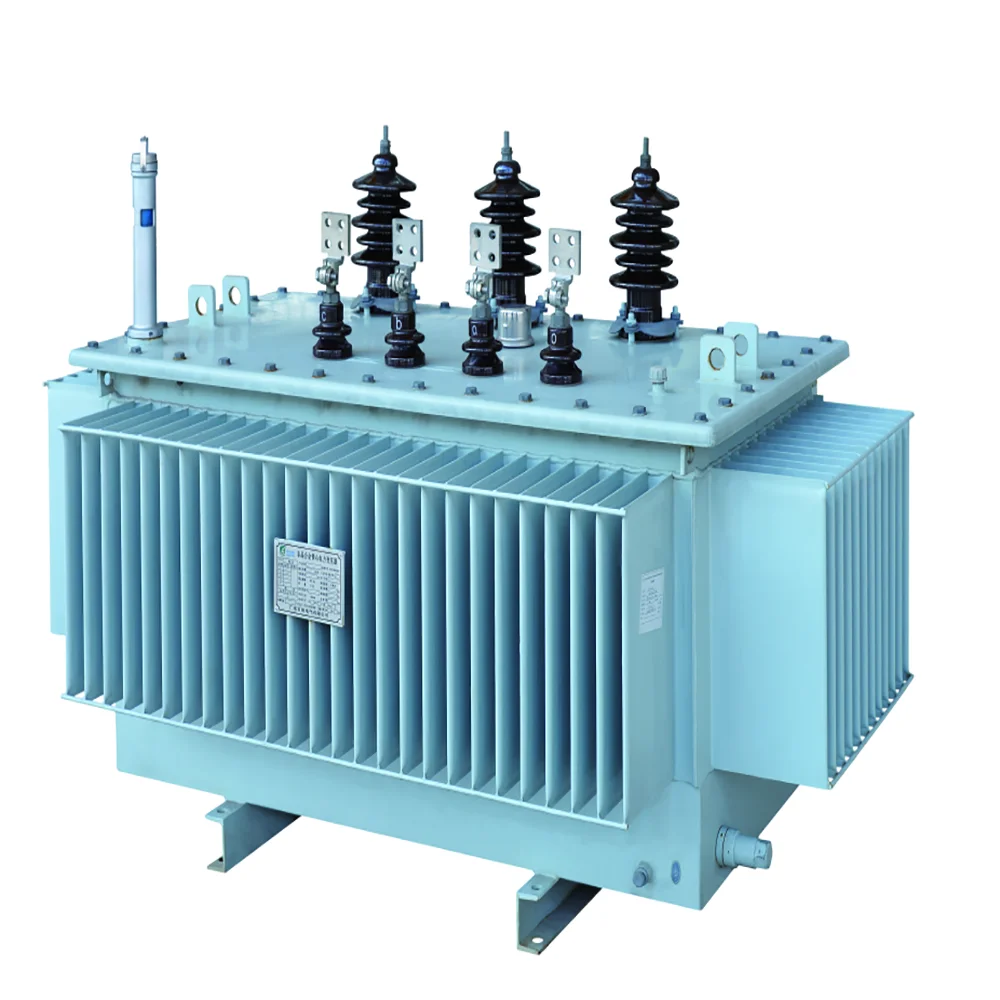

The Industrial transformers are a group of many sorts of specialist designs. Each of these types is designed to perform a specific function in the transmission, handling and use of electric power-from step-up transformers that increase voltage levels to step-down those simultaneously reduces them. The isolation transformers also play defensive roles for the electrical appliances as they prevent possible susceptibility to electric shocks by breaking off incoming and outgoing current.

When choosing an industrial transformer, there are many factors to consider. The transformer size is of utmost concern some are meant for home use and the others made just to fit in industrial environment. Further more the voltage of transformer should in sync with electrical device which it is going to use and this points ultimately lead us about Selection Of Voltage Level For Transformer.

Adopting of New Technological innovation in Manufacturing Power Transformers

Industrial Power TransformersThe world of industrial power transformers grows and expands as new technologies become available to increase energy efficiency,endure harsh operating conditions, protect against electrical surges... For instance, in the same way that phones and computers have been able to communicate with other devices for years, transformers are now being upgraded into smart technology so they can interact together. Smart transformers built to save electricity are already sensitive and can detect possible electrical problems at an early stage, thus reducing potential risks. In addition to this, they can control rhe discharge of electricity which leads directly to a stable and reliable energy generation.

So, in essentially rather terms we can say that industrial power transformers become quite an essential asset of our lives for a safer and better electricity use. We can have a better understanding of how transformers are so crucial is our day to day life through exploration in the types, influencing factors and technological advancements involved.

Our products have all undergone rigorous quality inspections and fully meet international standards, possessing industry certifications such as lSO, lEC, UL, CUL, CE, etc. In our company, we are proud to have comprehensive set industry-specific certification. These industrial power transformers aren't only indication of commitment safety and quality, they also prove to our rigorous compliance with international standards guidelines. products are subjected strict audits inspections ensure are meeting highest standards of performance standard, durability safety requirements. certifications cover a variety of aspects transformer production, including design, materials, production processes, testing. Having these certifications gives customers confidence that they are investing in an item that is safe as well as reliable and is guaranteed by firm that adheres to the most stringent standards of the industry.

We are of the opinions that sale of a transformer is just the beginning of our relationships with our customers. This is why we industrial power transformers and thorough after-sales services to make sure that customers receive the highest level of satisfactions and value for their investment. Will ensure that you receive prompt and efficient services, no matter if you need installation help or advice on maintenance, or technical assistance. We recognize that transformers critical components in various industries, and any downtime could have significant implications. Our staff is available to answers questions, provide assistance, and make sure that our customers' needs always met.

Our company has more than 1,000 employees, which industrial power transformers who have years of experience in the transformer industry. We offer professional solutions to our customers and provide support. Our technical team of experts is the cornerstone of our business. This team consists of highly-skilled engineers design, technicians and designers as well as quality control experts with a wealth of expertise and knowledge in transformer technology. Our team is dedicated to staying up-to-date with new trends in technology as well as the industry, ensuring that our products are up-to-date and competitive. Our technical team collaborates with our customers understand their individual requirements and to provide specific solutions to meet their requirements. They also responsible for overseeing the entire manufacturing process, from designing and engineering through manufacturing and quality inspection making sure that every transformer we produce is of the highest standards and performance.

For the past 18 years, our company has been at forefront of the transformer industry. We have our own factory and offer a range of customized services. We have established an extensive base of experience and know-how over the years, which has allowed us to keep ahead our competition. We've accumulated vast knowledge and experience throughout time, allowing us to anticipate market trends create innovative solutions that fulfill the evolving demands of our customers. We've refined our skills in the design of products well as manufacturing processes and quality assurance, which means every transformer we create is not just reliable, but also exceeds industry standards. We have built industrial power transformers connections with our suppliers' customers, and partners over the years, further strengthening our position in the market.